Our product's categories / applications

Fuel cell bipolar plates / Ref. FUEL-CELLS / Status: available

Quickly, precisely and non-destructively measuring coatings deposited on bipolar plates in fuel cells and electrolyzers is still a challenging task for existing sensor technologies. Precitec now offers a breakthrough technology for this through Enovasense laser photothermal sensors.

Zinc-based paint on brake discs : thickness measurement / Ref. ZINCPAINTBRAKE / Status: available

Measuring quickly, precisely and non-destructively anticorrosion paints deposited on any area of the brake discs is still challenging for existing sensor technologies. Precitec now offers a breakthrough technology for this with Enovasense laser photothermal sensors.

Laser cladding layers on brake discs : thickness control / Ref. LASERCLADDING / Status: available

Quickly, precisely and non-destructively measuring laser-cladded

layers on brake disc tracks is still a challenging task for existing

sensor technologies. Precitec now offers a breakthrough technology

through Enovasense laser photothermal sensors.

Controlling coatings and treatments on fastening systems / Ref. FASTENERS / Status: available

Fast, precise and non-destructive measurement of the coatings and surface treatments deposited on any area of fastening systems is still a challenging task for existing sensor technologies. But with Enovasense laser photothermal sensors Precitec can now offer a breakthrough technology that masters the challenge.

Controlling coating thickness in coil-coating processes / Ref. COIL_COATING / Status: available

Quickly, precisely and non-destructively measuring coatings deposited through coil-coating processes is still a challenging task for existing sensor technologies. But now Precitec offers a breakthrough technology using laser photothermal sensors.

Paint on battery cells : thickness measurement / Ref. BATTERYCELL / Status: available

The Laser Photothermal technology proposed by Precitec Enovasense brings a unique new offer in the field of battery pack paint applications. This technology allows measurements that are non contact, non destructive, non intrusive, non radiative, fast, repeatable and easy to integrate. Opening this way access to an easy in-line and at-line measurement integration with a cost-effective positioning.

Powder paint : thickness measurement / Ref. POWDER / Status: available

- Non destructive, contactless and fast measurement

- Very compact measuring head

- High measurement repeatability

- Works on epoxy and polyester paints on metallic, polymers and composite substrates, also on enamel coatings

- Allows to measure parts moving on vertical and horizontal conveyors

- Automated storage and archiving of referenced measurement data

- Live stream of data to line controller

Electrode films for electric batteries : weight, porosity, thickness measurement / Ref. BATTERIES / Status: available

Electric batteries electrodes are produced from metallic bands coated with a graphite carbon layer, a metal mix or a metalic oxide.

The control of the thickness and the density of this layer is important to obtain the right properties of the electrical battery.

The Enovasense technology allows to realize the measurement of the thickness and of the density in the production line while the band is moving at high speed, using a non intrusive principle only needing 1 sensor on 1 side of the band.

Coatings on orthopedic implants : thickness measurement / Ref. PROTHESES / Status: available

The Enovasense technology, especially integrated into the Hako L control station allows to make fast and contactless measurement of the thickness of metallic and ceramic deposition on medical implants.

This is especially important for titanium or hydroxyapatite (HAP) deposited by plasma spray or by other means on hip, knee, finger... implants and prostheses.

The Hako L control station allows to automate series of measurement points in different locations of a part and to scan by this way groups of several parts in a fast and repeatable way.

Pyrolitic carbon and vapor deposited ceramic carbides (CVD) : thickness measurement / Ref. CARBON / Status: available

Chemical vapor deposition (CVD) processes for coatings of pyrolytic carbon and/or ceramic carbides give to graphite, composite, metallic, ceramic substrates some technical characteristics of very high performances, due to the nature of the coatings but also to their specific microstructure.

The control of the deposited thickness is then imperative for those applications, especially due to the process of CVD, with the variations of thickness being possibly very important inside a given cycle, a given chamber or even on a given part in different zones.

Aluminum anodizing : thickness measurement / Ref. ANOD / Status: available

Aluminum anodizing is an electrochemical process allowing the protection of aluminum against corrosion and their colouration. The principle is to artificially grow the alumina layer on the surface of an aluminum part.

The thickness of the layer created is directly linked to the level of protection and the durability of the part. It is so essential to do a precise control of the anodizing thickness in order to ensure the anticorrosion effect needed.

Enovasense revolutionizes the measurement of the thickness of aluminum anodizing by proposing an automated control station, allowing to perform measurements that are precise, repeatable, independant of the curvature, of the shape or of the size of the parts.

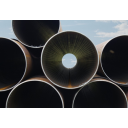

Coatings and paints in tubes and pipes : thickness measurement / Ref. PIPE / Status: available

Tubes and pipes used for example in the Oil and gas, drinkable water or chemestry industry often have anticorrosion coatings deposited on the outside or on the inside.

Those coatings can be special paints, thermoplastic polymers or metallic layers deposited by plasma thermal spray or galvanising.

The Enovasense technology provides a solution for measuring the thickness of those coatings that is non destructive, fast, integrable into the production line for a measurement of the exterior or interior of the tubes.

Metallic and ceramic coatings deposited by plasma thermal spray : thickness measurement / Ref. PLASMA / Status: available

Thermal spray coatings consist in sending the coating material (powder or wire) in a heating medium (plasma, electric arc...) and/or with a certain speed (HVOF) before having it go on the substrate with a certain fusion and speed level allowing it to bind.

Those coatings are used in various industrial fields such as aeronautic engines, automotive engines, biomedical bone prostheses or gaz turbines.

The need of a thickness control technology for the deposited coating is essential due to the structure of the coating in surface and inside the matter, to the deposited thickness level and to the technicity of the produced parts.

Coatings and adhesives on extruded EPDM rubber : thickness measurement / Ref. EPDM / Status: available

Extruded bands of EPDM or rubber are used in several applications, primary in the sealing market (like for automotive door sealing) or also in the wipers industry.

Due to the frictions resulting from those parts when touching the materials on which they are in contact (metal, glass), it is necessary to use anti-friction slip coatings. When the thickness of those coatings is too small, the anti-friction property is no longer reached, which can lead to an increased wear of the parts.

The Enovasense technology, not only allows to check very precisely and very quickly the thickness of those kind of coatings, but also allows to perform the measurement in-line, when the moving mand leaves the coating process step.

Automotive engine cylinder blocks iron coating : thickness measurement / Ref. CYLINDER / Status: available

Bore-Spray Coating is a technical innovation recently implemented in an increasing portion of automotive engines. Instead of using full iron casting cylinders, automotive suppliers use aluminum cylinders with an iron coating inside the cylinder in order to decrease dramatically the weight of the engine while keeping antifriction and hardness properties of iron.

Measuring the thickness of this coating in several angles and heights in each cylinder is so important to ensure quality and durability of the engine but also to assess any drift in the coating and boring processes.

Conformal coatings on PCBs : thickness measurement / Ref. CONFORMAL / Status: available

- Contactless and non destructive

- High measurement repeatability

- Sensor easy to automate for in-line or out-of-line reliable and reproduceable measurement and up to 100% control

- Measurement also available on wet conformal coatings, before curing

- Large range of thickness values covered, even for sub-micronic coatings

- Automated storage and archiving of referenced measurement data

- Live stream of data to line controller