Applications / coatings and adhesives on extruded epdm rubber : thickness measurement

Extruded bands of EPDM or rubber are used in several applications, primary in the sealing market (like for automotive door sealing) or also in the wipers industry.

Due to the frictions resulting from those parts when touching the materials on which they are in contact (metal, glass), it is necessary to use anti-friction slip coatings. When the thickness of those coatings is too small, the anti-friction property is no longer reached, which can lead to an increased wear of the parts.

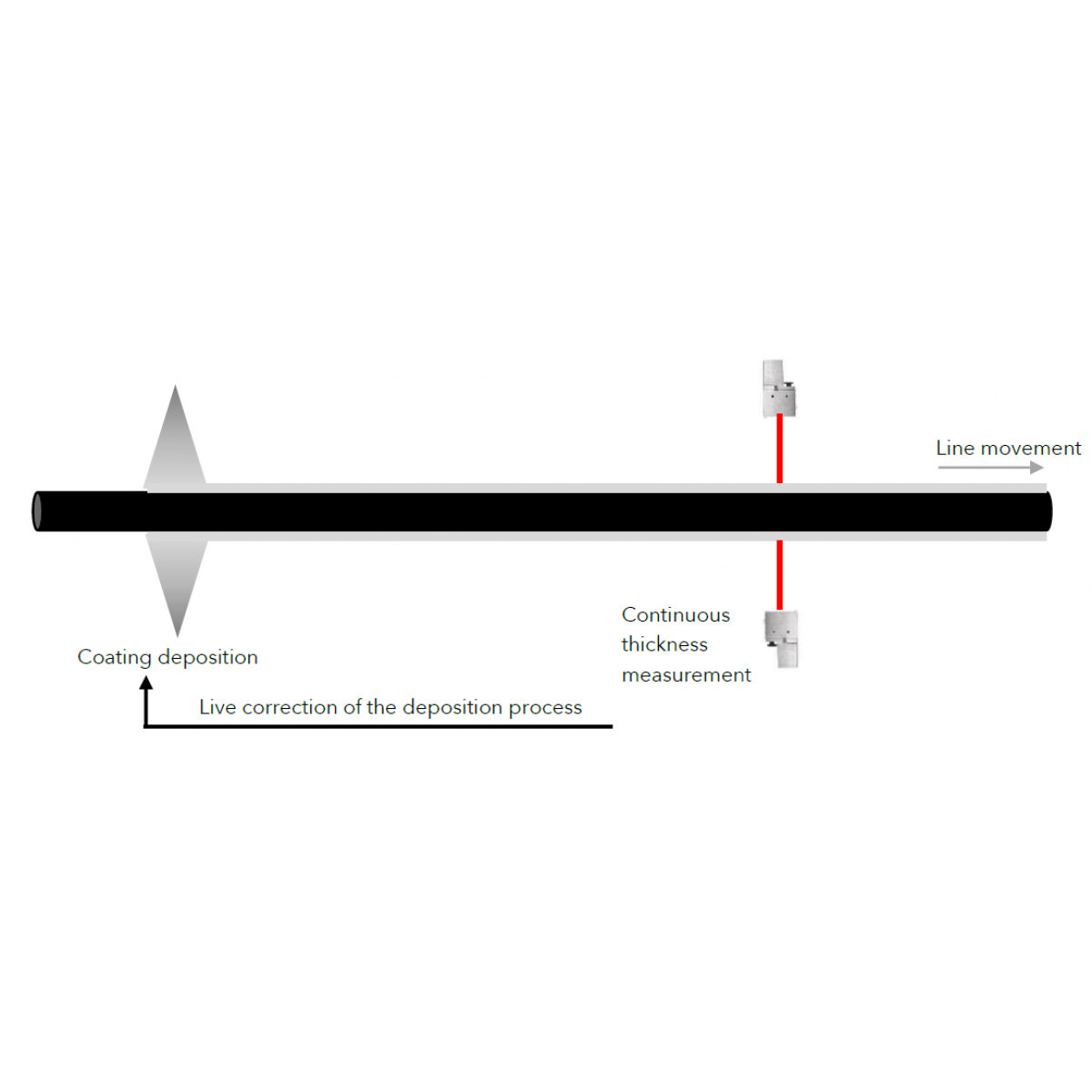

The Enovasense technology, not only allows to check very precisely and very quickly the thickness of those kind of coatings, but also allows to perform the measurement in-line, when the moving mand leaves the coating process step.

Coating deposition :

- Contactless and non destructive

- In-line measurement during part fast movement

- Multiple measuring head technology possible for multiple points measuring at the same time

- High repetition rate for continuous following of the thickness

- Available for all kinds of coatings (solvent and water base…)

- Automated storage and archiving of referenced measurement data

Advantages and savings :

- In-line measurement allows an immediate correction of the deposition process and better quality and consumption management

- Nondestructive and fast measurement allows to improve precision, gain time and increase the number of data