Applications / paint on battery cells

In the e-mobility industry, battery packs are increasingly coated with UV cured or epoxy paints. Those paints ensure an overall high dielectric protection of the battery pack through an easy and reliable application process. Controlling the thickness of this paint in many areas, especially in the most critical ones like the angles of the cell, is mandatory to ensure the durability of the electrical insulation provided by the paint. An in-line control is also important to monitor and optimize the deposition processes. The existing contact measurement technologies like magnetic sensors show low repeatability levels and high dependency on the operator.

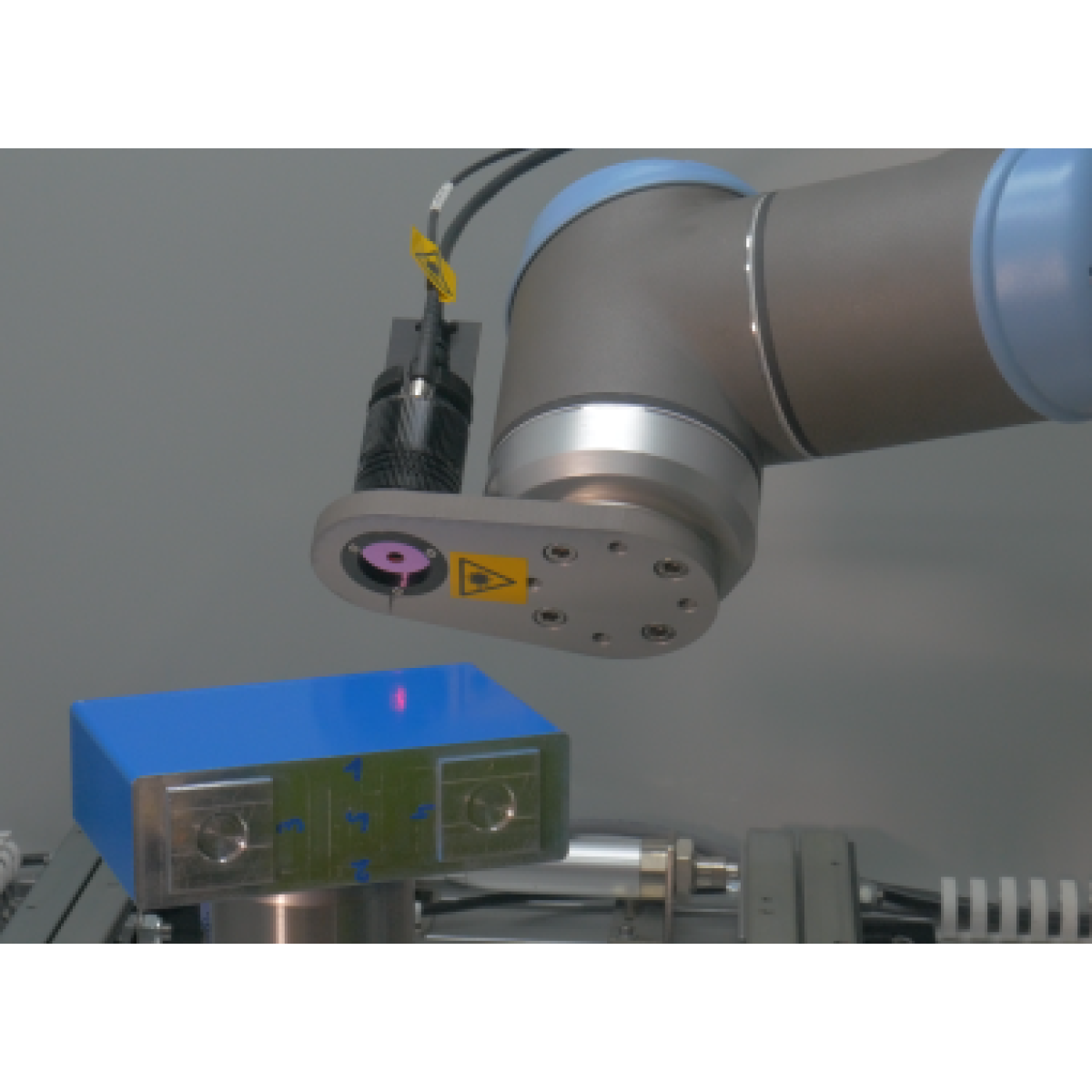

IN-LINE OR AT-LINE MEASUREMENT

The Enovasense sensor technology can measure the entire surface (sides, corners, edges, etc.), with an outstanding level of precision. RMS repeatability levels down to 0.3µm can be obtain on a typical 100µm thick layer.

The optical probe can easily be integrated inside the production process due to its ultra-compact dimensions and low weight (down to 150g), its high tolerance on the distance (±10mm) and angle (±50°) and its independence on part curvature, vibrations, or temperature. The measurement data are automatically stored and archived; data are streamed in live communication to the line controller.

The sensor can also be embedded in the fully automated 3-axes control station HKL2 for at-line measurement. In this control station, pre-programmed cycles allow to cover many measuring points on a given battery cell in a few seconds. Moreover, for development or process setup, a full mapping of a part can be achieved automatically through a simple interface.