Applications / aluminum anodizing

Precise thickness measurement of anodized aluminium

Aluminum anodizing is now a standard production process in many industrial sectors, including aerospace, automotive, and mechanical engineering, and consumer electronics such as mobile devices. It is no longer limited to a cosmetic function, but a process that directly affects corrosion resistance, mechanical durability, and compliance with industry regulations. The thickness of the anodized layer is therefore a functional variable, not a cosmetic one, and must be accurately measured to ensure process conformity and effective surface protection.

Anodizing process

Anodizing is an electrochemical process used to treat aluminum. The aluminum is immersed in an electrolytic bath of sulfuric acid, to which an electric current is applied. The treated part acts as an anode, causing a porous aluminum oxide deposit to grow on its surface, the thickness layer depends on the physical and chemical conditions of the electrolytic bath. After application, the coating can be sealed to reduce its porosity and improve its corrosion resistance. Accurate, repeatable, and reproducible thickness measurement is a key issue for manufacturers.

Why anodic layer thickness is difficult to measure

Measuring anodized layers is inherently complex due to the nature of the process itself.

There are generally two main methods used in the industry : eddy current measurement, which is ineffective for thin layers and difficult to implement on parts with complex geometries due to the need for multiple calibrationsor impossible on small size parts. And optical methods (white light interferometry / spectral reflectometry), which are difficult to scale to industrial production due to the mechanical complexity of their implementation.

In contrast, Enovasenseʼs photothermal method enables accurate, repeatable, and reproducible measurements regardless of part geometry, with low mechanical constraints on sensor positioning, making it an easily scalable solution for industrial deployment. It is an ideal solution for all kinds of anodizing (hard, sulfuric, chromic) on all kinds of aluminum alloys.

| Criteria | Enovasense photothermal | Eddy current | Optical Interference (White Light Interferometry / Spectral Reflectometry) |

|---|---|---|---|

| Measurement principle | Thermal diffusion response | Electrical conductivity response | Analysis of interference fringes from reflections at air / anodizing / aluminum interfaces |

| Destructive / non-destructive | Non-destructive | Non-destructive but with contact | Non-destructive |

| Sensitivity to surface condition | Low to moderate, compatible with complex geometries | Moderate | Very high (roughness, porosity, scattering) |

| Sensitivity to part geometry | Low | High (contact, orientation) | Very high (requires near-normal incidence, flat surfaces) |

| Local representativity | Local measurement with mapping capability | Point measurement, often non-representative | Very local measurement |

| Measurement of thin coatings (few µm) | Working for all functional thicknesses | Limited accuracy for thin anodic layers | Very good for thin, uniform layers |

| Tolerance to distance variations | High | Low (contact) | Very low |

| Automation / inline integration | High (robot integration, thickness mapping) | Difficult | Not suitable |

| Measurement cycle velocity | High | High | Low (alignment, vibration sensitivity) |

Intercomparison thickness measurement of Anodic thickness layer

Enovasense technology has proven itself on real samples from industrial suppliers. Regarding the accuracy of the measurement, Enovasense performed a test study on samples that showed various thickness levels covering the whole range of the tolerance interval, from 1 to 25µm.

Note : We also have performed a similar study in the low thickness interval (between 0 and 5µm) where the performances were optimized. The results are shown in the next section

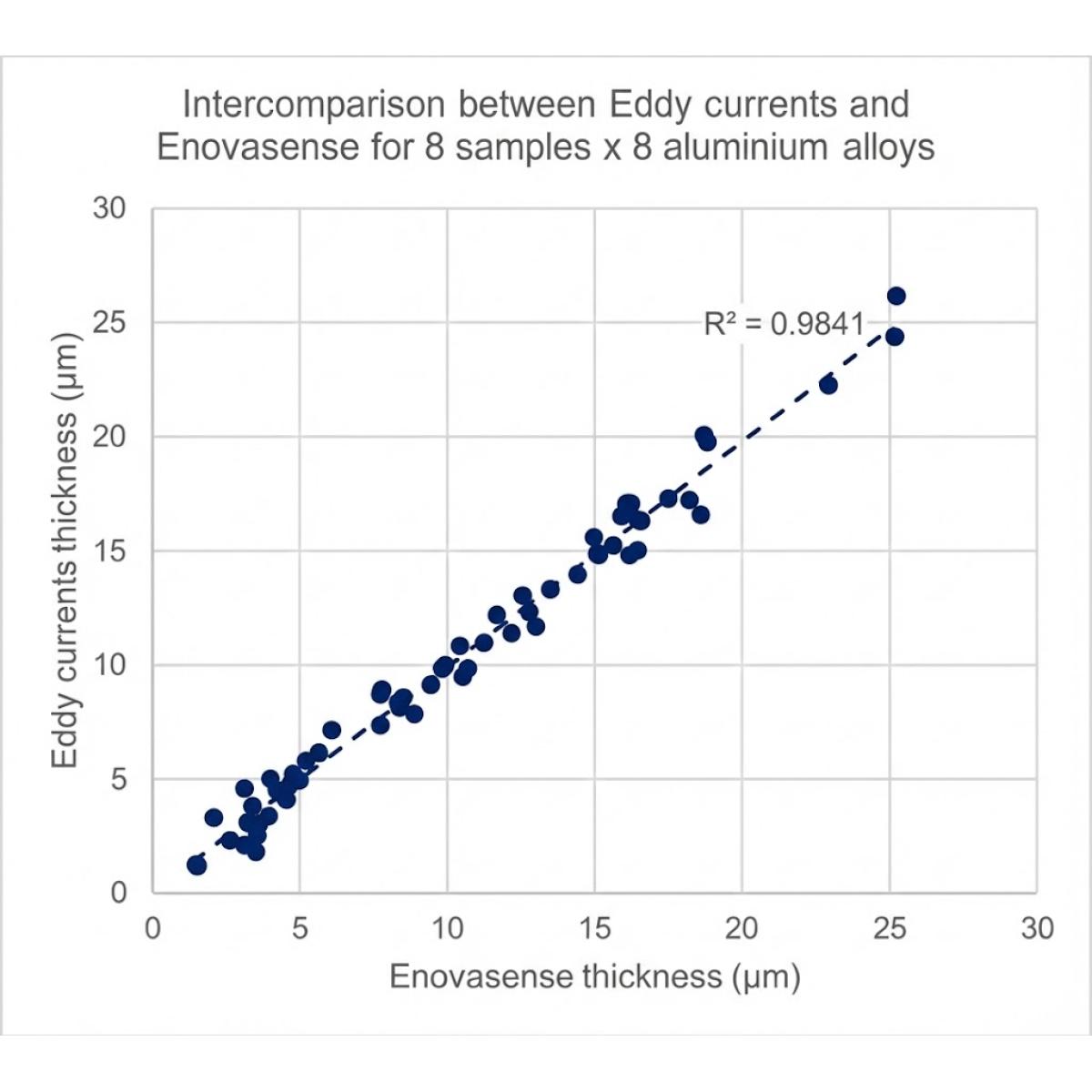

8 aluminum alloys series were analyzed : 1050, 2017, 2024, 2618, 5083, 6061, 6082 and 7075. For each alloy series, 8 samples were treated by anode sulfuric oxidization. The immersion duration enabled to create different oxide thicknesses between 1 and 25µm. We measured the oxide thickness using Eddy currents as a reference. The figure below shows the average thickness measured for each sample in correlation to the Eddy current reading :

We observe a 98% correlation between both techniques with an average difference of only 0.6µm.

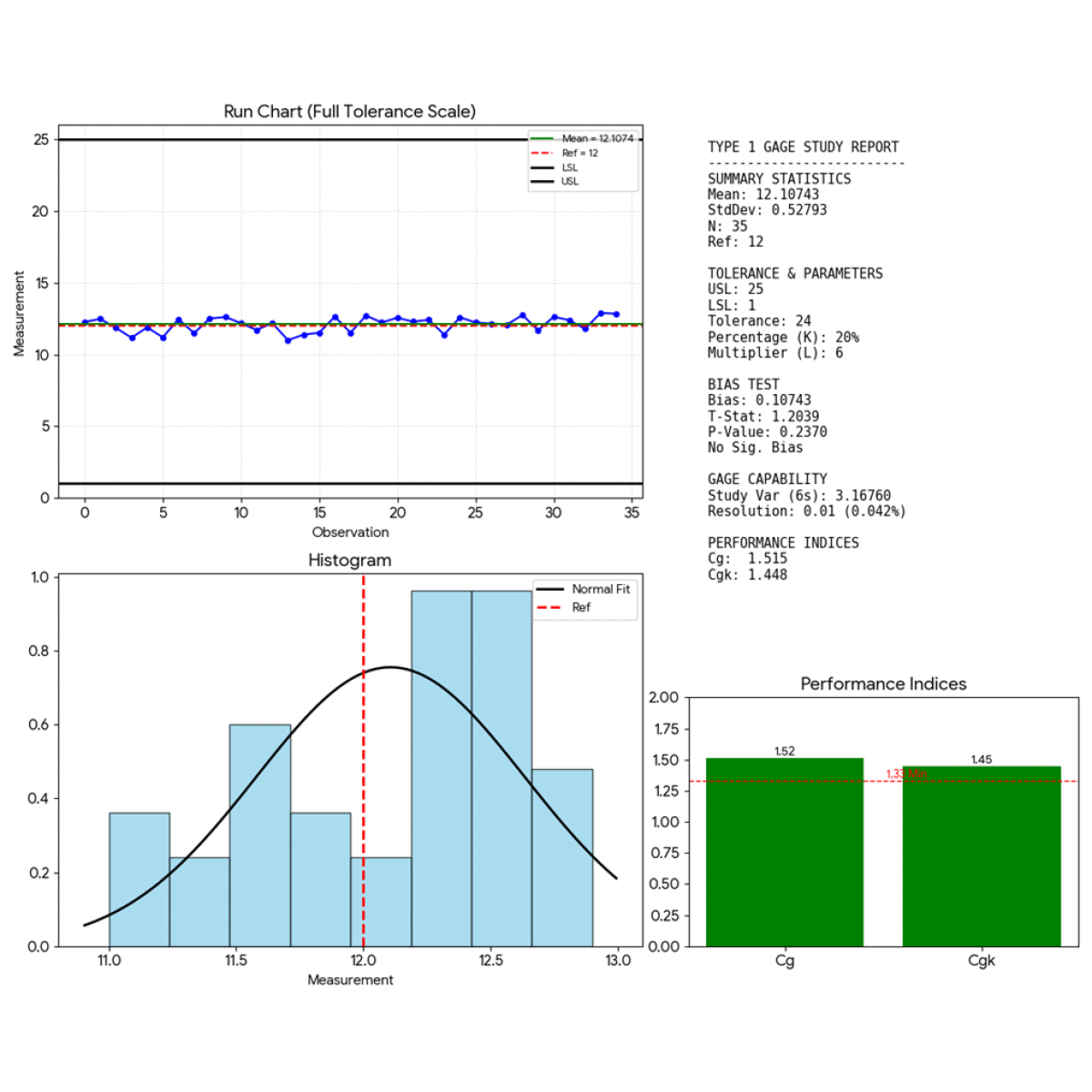

We also performed a type 1 MSA study on a sample in the middle of the range showing a target value of 12µm.

- Bias: The P-Value (0.237) is greater than the significance level of $0.05$. Therefore, the bias is not statistically significant. The gage is accurately centered on the reference value.

- Capability: Both Cg (1.52) and Cgk (1.45) exceed the standard threshold of 1.33. This confirms that the measurement system is capable. The variation is appropriately small relative to the tolerance of 24 units.

Test study on the low thickness range

Regarding the performances, the Enovasense technology can even be optimized for anodizing of casings of mobile devices (consumer electronics applications) where the thickness of the layer is lower (below 5µm).

For those cases, as Eddy currents are not performing well, optical interference techniques are widely use as they allow to reach very high precisions.

In the following measurement intercomparison, we find out that not only the Enovasense technology is easier and faster to implement than optical techniques (no precise alignment, no impact of surface condition or part geometry), but also it shows similar measurement performances (accuracy and repeatability).

How to integrate Enovasense technology for anodic coatings

Offline station : the HKL2 control station

It allows to perform thickness mappings and cycles of movements and measurements in order to automatically measure various positions on the part with a 3 axes sytem.

Inline integration : industrial robot

The enovasense measurement solution can be integrated directly inline, giving real-time monitoring of anodic deposition. By using a six-axis robotic system, it enable the access to complex geometries such as fillets, curved surfaces, and side features.

References

| Réference | Name | Status / Price | Datasheet |

|---|---|---|---|

| ANOD | Control station for aluminium anodizing thickness control |

Available

On quotation |

English French |

| ADVANTAGES | Why use Enovasense Hako L to measure aluminum anodizing thickness ? |

Available

On quotation |

English |

Documents

| Type | Name | Download |

|---|---|---|

| Certification | Why use Enovasense HAKO L to measure aluminum anodizing ? | English |