Applications / aluminum anodizing

Aluminum anodizing is an electrochemical process allowing the protection of aluminum against corrosion and their colouration. The principle is to artificially grow the alumina layer on the surface of an aluminum part.

The thickness of the layer created is directly linked to the level of protection and the durability of the part. It is so essential to do a precise control of the anodizing thickness in order to ensure the anticorrosion effect needed.

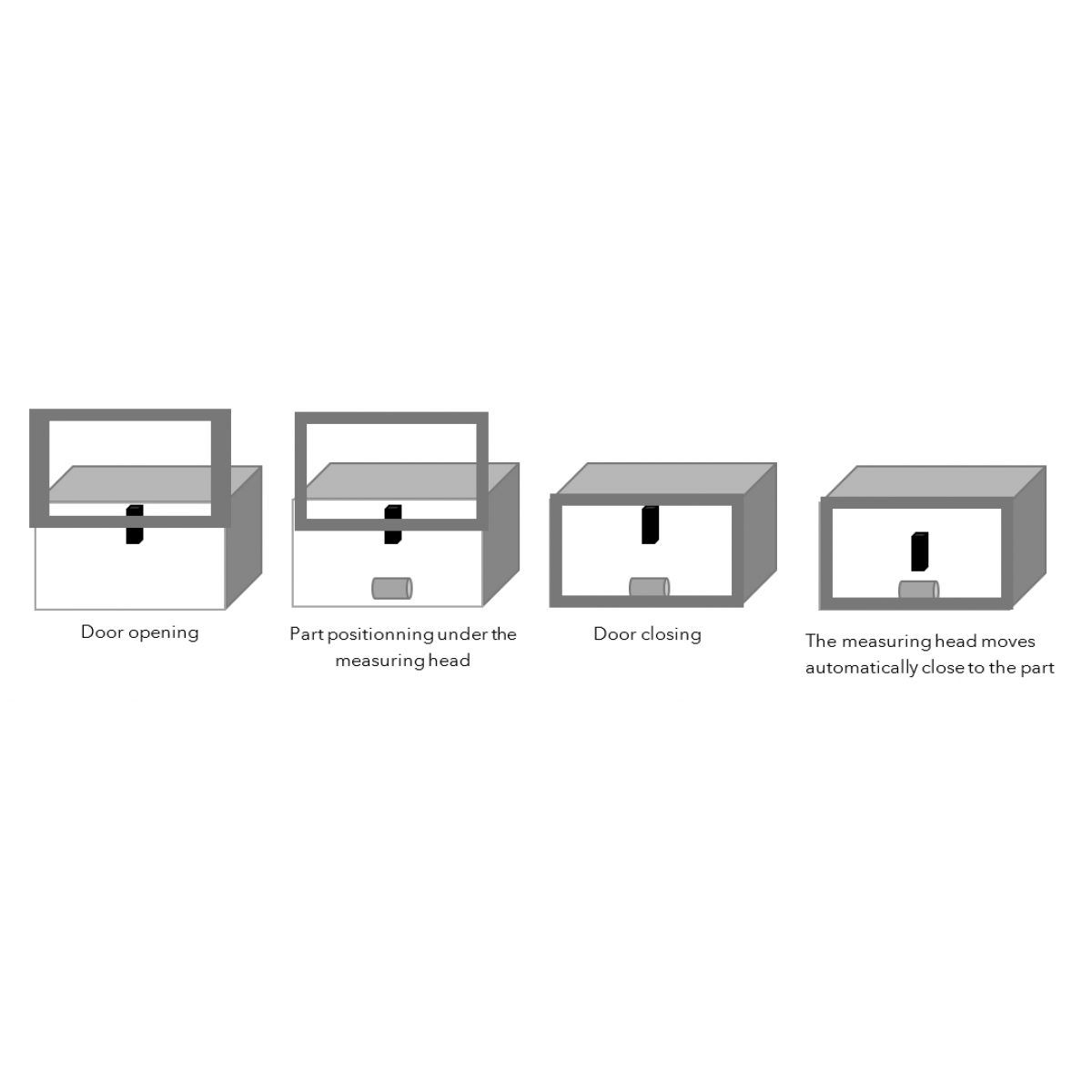

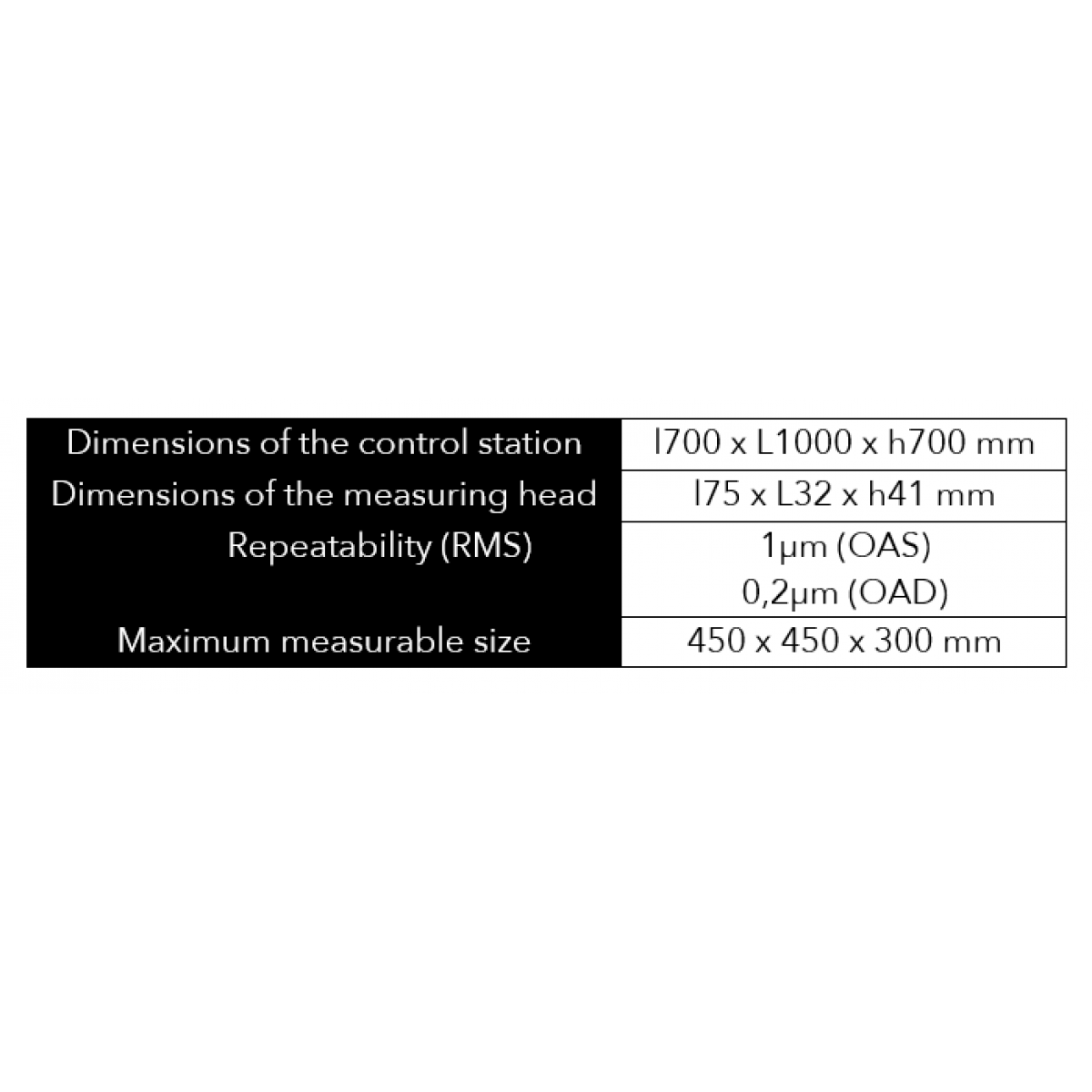

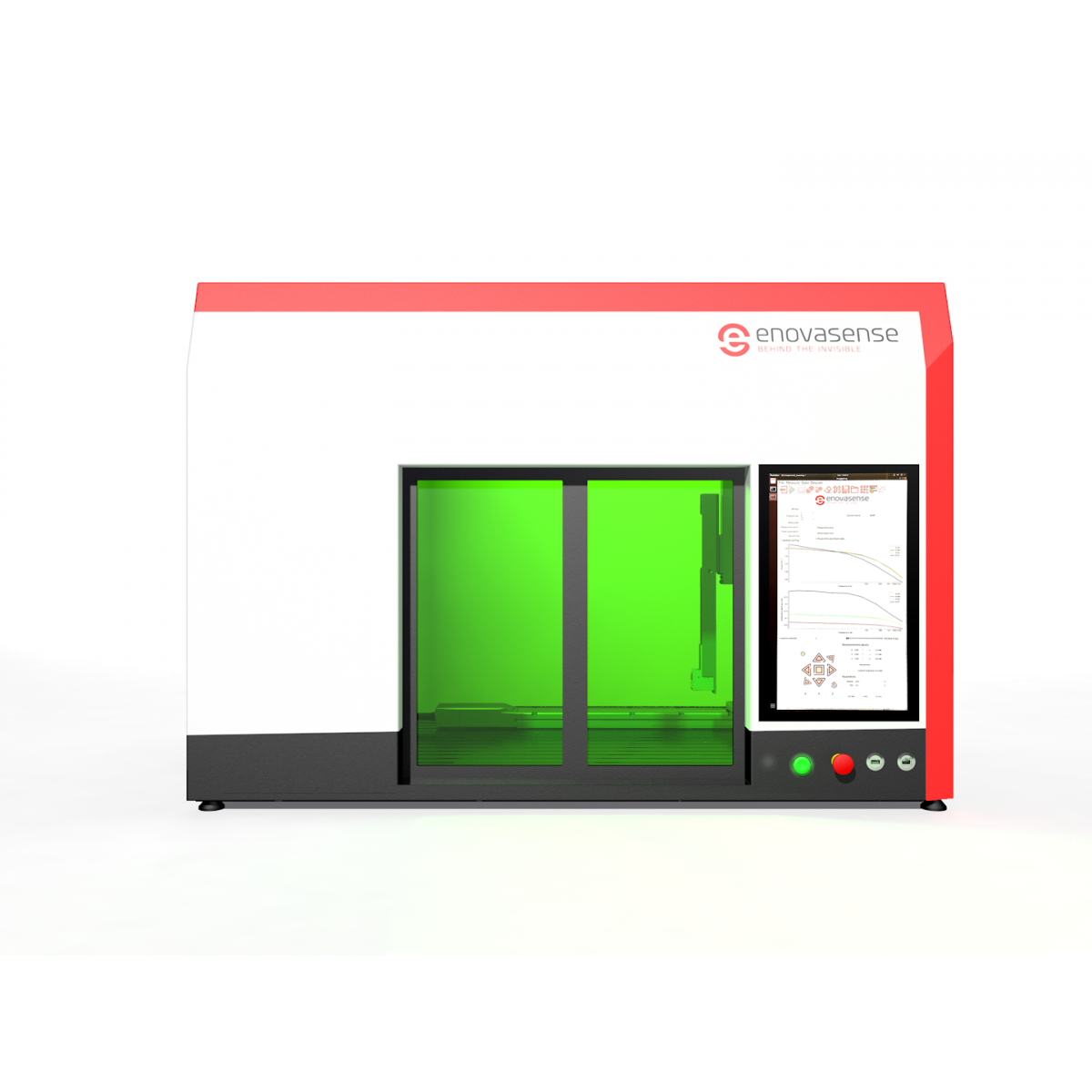

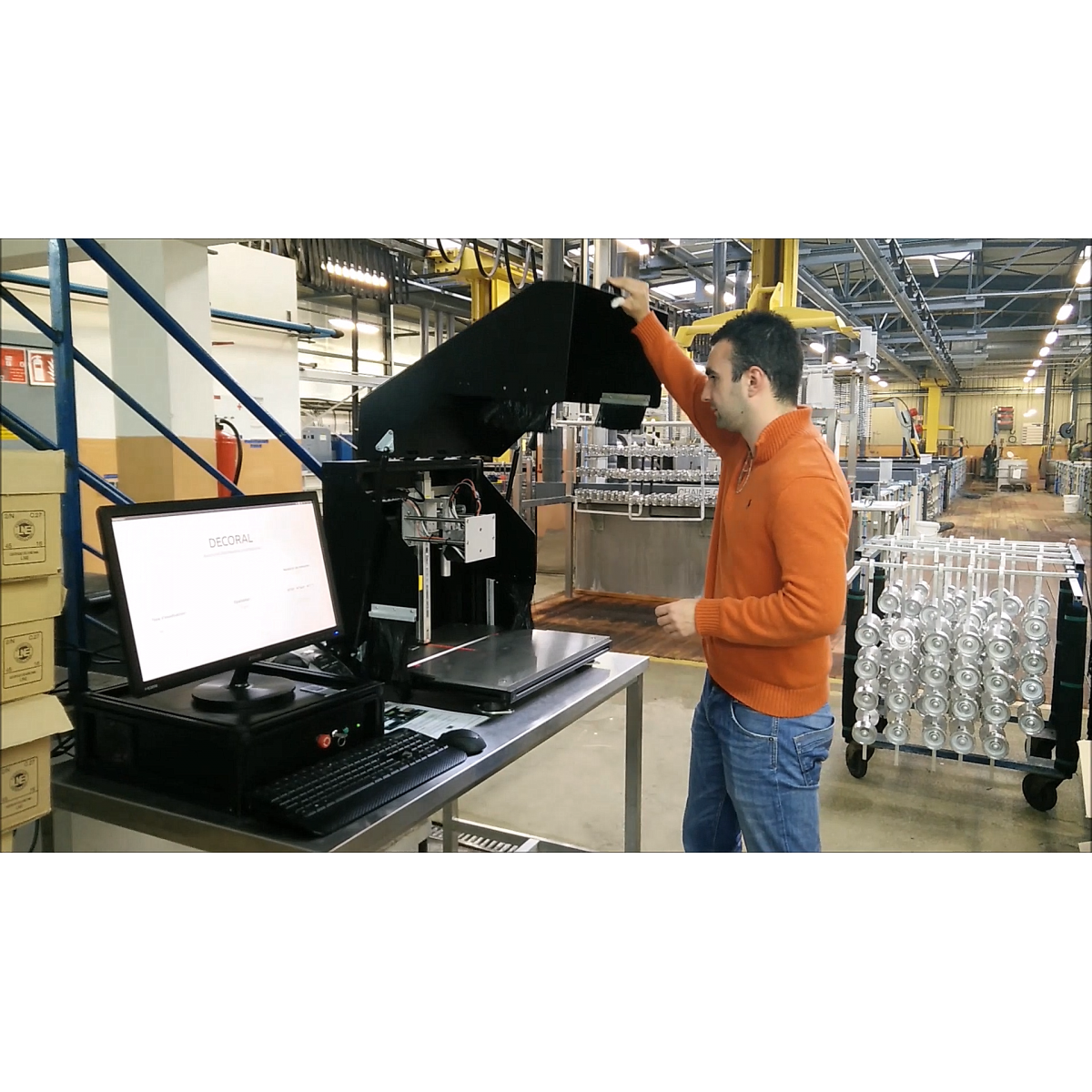

Enovasense revolutionizes the measurement of the thickness of aluminum anodizing by proposing an automated control station, allowing to perform measurements that are precise, repeatable, independant of the curvature, of the shape or of the size of the parts.

Control station installed at the end of production line or at quality control

- Contactless

- Non destructive

- Working on all surfaces, even the smallest and curved, and on threadings

- Unique and permanent calibration for all kinds of aluminium and all parts shapes

- Working on hard, sulfuric and chromic anodic oxydation

- Measurement precision of 1µm

- Automated storage and archiving of referenced measurement data

Advantages and savings :

- Contactless system reduces repeatability problems and increases precision of the measurement.

- Unique calibration simplifies the use, allows time savings and avoid confusions

- Contactless system increases the lifetime of the probe and avoids regular replacements

References

| Réference | Name | Status | Price | Datasheet |

|---|---|---|---|---|

| ANOD | Control station for aluminium anodizing thickness control | Available | On quotation | English French |

| ADVANTAGES | Why use Enovasense Hako L to measure aluminum anodizing thickness ? | Available | On quotation | English |

Documents

| Type | Name | Download |

|---|---|---|

| Certification | Why use Enovasense HAKO L to measure aluminum anodizing ? | English |