Applications / zinc-flake coatings on brake discs

Non Contact Thickness Measurement of zinc flakes anti corrosion coatings on automotive brake discs

Since the early 2000s, zinc-flake coatings have become the dominant anti-corrosion solution for automotive brake discs. As a result, accurately measuring coating thickness has become a key challenge for the automotive industry, in order to ensure sufficient corrosion protection while controlling process costs.

Brake disc coating quality control is essential in the automotive industry.

Brake discs are exposed to aggressive environmental conditions such as humidity, saline fog and temperature variations, that can lead to corrosion and deterioration of the brake disc, both from an aesthetic and functional point of view. Thus the zinc-flake coating protects the non-friction areas of the brake disc.

As a result, OEM (Original Equipment Manufacturer) specifications impose strict requirements on zinc-flake coating thickness, uniformity, and corrosion resistance, making reliable and repeatable the control of zinc flake coating on brake disc.

Zinc-flake coating structure

The zinc-flake coating is a layering of thin lamellar zinc particles dispersed in an inorganic binder resulting in an inhomogeneous and non-isotropic coating due to the random orientation and stacking of zinc-flakes within the binder matrix.

This type of coating is typically sprayed onto the brake disc surface, before being baked. As a non-electrolytic deposition method, it enables controlled and uniform application even at low thicknesses, typically ranging from a few micrometers to a few tens of micrometers. It also avoids issues such as hydrogen embrittlement and allows consistent coverage of complex geometries.

Such zinc-flake coating are widely supplied by established manufacturers in the automotive industry, such as NOF Metal Coatings, Magni, Wörwag or Dörken.

Why zinc-flake coating thickness is difficult to measure

The lamellar structure of zinc-flake coatings makes measuring their thickness a real challenge. Indeed, they combine thin layers, rough surfaces, a non-isotropic microstructure, and strong industrial constraints. As a result, many conventional thickness measurement methods struggle to deliver repeatable and reproducible results. This highlights the need for measurement approaches based on an integrated physical response of the coating–substrate system.

Technical Challenges in Zinc-Flake Coating Thickness Measurement

Conventional industrial approaches to measuring the thickness of zinc-flake coatings, such as eddy current probes and X-ray fluorescence, have numerous technical limitations. Their response is highly dependent on the coating structure and part geometry, and their repeatability and reproducibility are often operator-dependent, making in-line integration difficult. While X-ray fluorescence is commonly used as a non-destructive reference technique, it requires radioprotection measures, is limited to small parts, and involves relatively long measurement times, which restricts its use in production environments.

Enovasense approach relies on an integrated thermal response of the coating–substrate system, making them less sensitive to local microstructural variations while remaining compatible with industrial automation.

| Criteria | Enovasense photothermal | Eddy current | Elemental X-ray fluorescence (Zn signal) |

|---|---|---|---|

| Measurement principle | Thermal diffusion response | Electrical conductivity response | Elemental X-ray fluorescence (Zn signal) |

| Destructive / non-destructive | Non-destructive | Non-destructive | Non-destructive |

| Sensitivity to lamellar microstructure | Low to moderate | High (flake orientation dependent) | Moderate |

| Sensitivity to surface roughness | Low | High | High |

| Sensitivity to non-isotropic properties | Low | High | Moderate |

| Measurement of thin coatings (few µm) | Well suited | Challenging | Possible but noisy |

| Repeatability / reproducibility | High | Operator- and calibration-dependent | Geometry- and setup-dependent |

| Measurement before curing | Possible | Not suitable | Not suitable |

| Automation / inline integration | Well suited | Difficult | Not suitable |

| Measurement velocity | High | High | low ~30 sec |

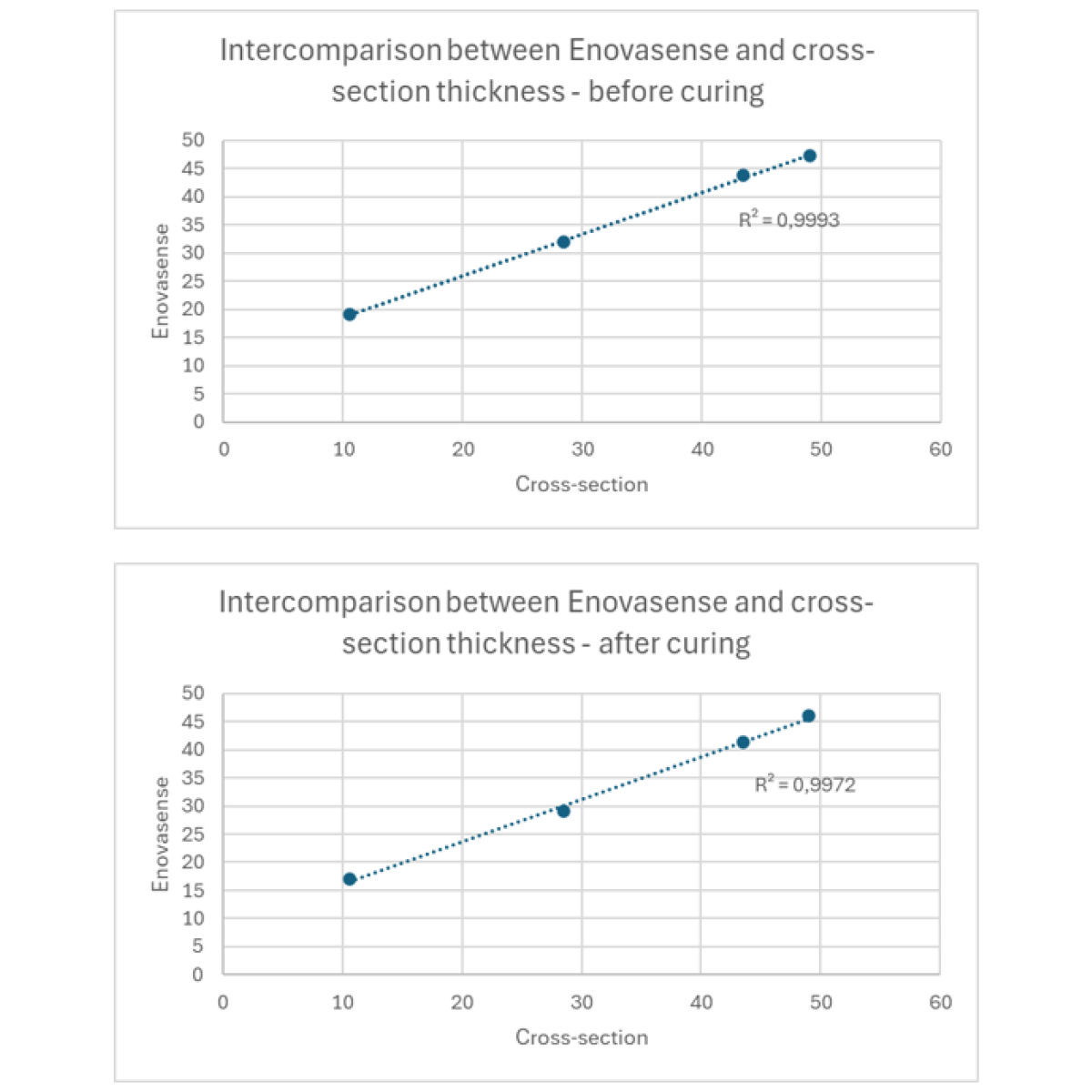

Intercomparison thickness measurement of Zinc-flakes coating

Enovasense technology has proven itself on real samples from automotive industry suppliers. Regarding the accuracy of the measurement, Enovasense performed test on samples that showed various thickness levels covering the whole range of the tolerance interval. Those measurements were then compared with microscopic cross-section measurements, which is considered here as the destructive reference method.

There is a strong correlation between the values obtained by microscopic sectioning and those obtained using the enovasense sensor. It is also worth noting the method's ability to accurately measure the thickness before and after curing.

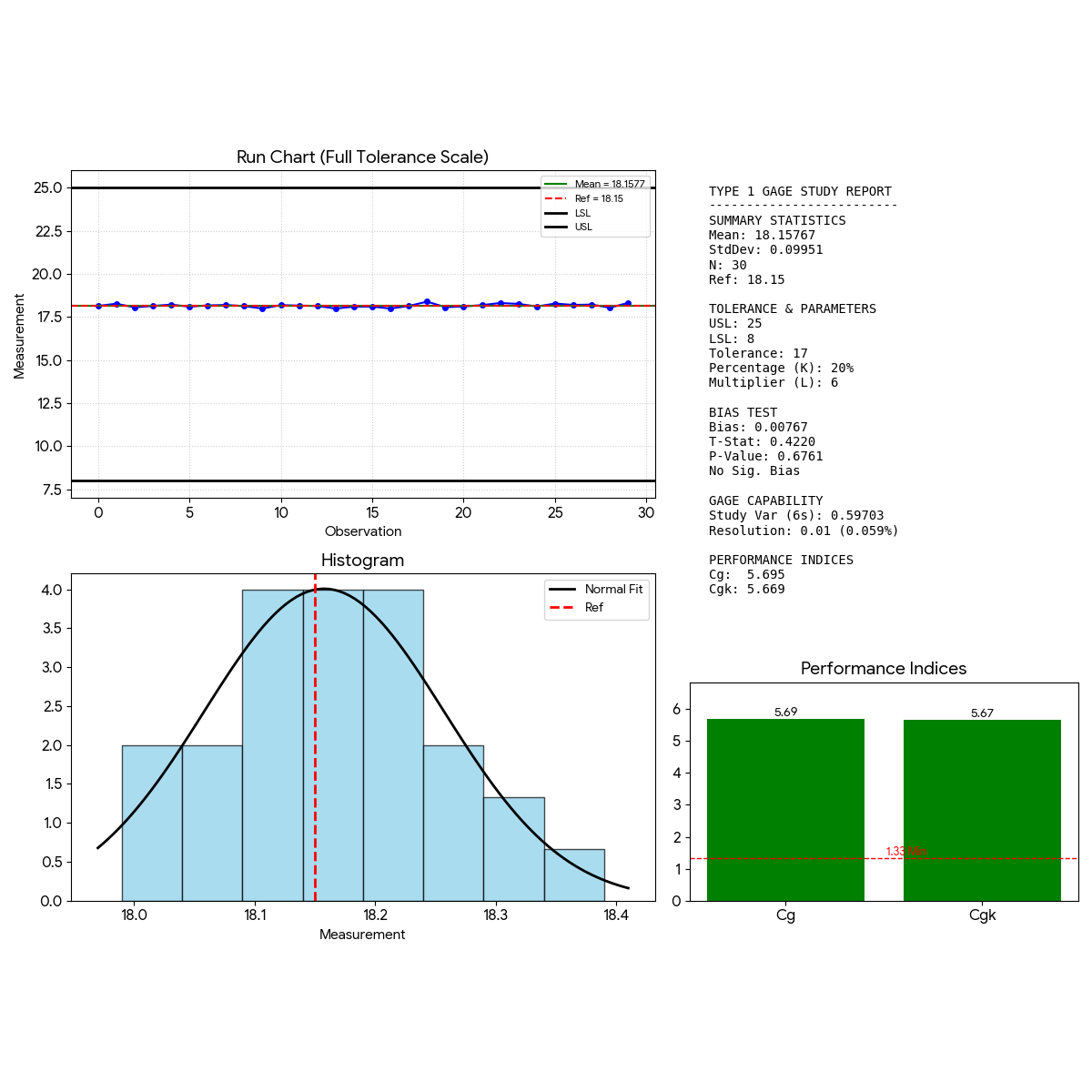

To further assess the intrinsic performance of the measurement system, a Type 1 Measurement System Analysis (MSA) was conducted on a representative sample under controlled conditions.

- Bias : The P-Value (0.676)is higher than the standard alpha level of 0.05. Therefore, the bias is not statistically significant. The measurement system is accurate relative to the reference.

- Capability : Both Cg (5.69) and Cgk (5.67) exceed the standard threshold of 1.33. This indicates that the measurement system is capable. The variation is acceptably small compared to the allocated tolerance.

How the Enovasense sensors can be integrated for brake discs measurement

The HKL2 control station

It allows to perform thickness mapping and cycles of movements and measurements in order to automatically measure various positions on the part with a 3D axis system.

The HKLR control station

It allows automated thickness mapping through programmed motion and measurement cycles using a 6-axis robotic system, enabling access to complex geometries such as fillets, curved surfaces, and side features that cannot be measured with conventional 3-axis systems.

Inline integration

The enovasense measurement solution can be integrated directly inline, giving real-time monitoring of zinc flake coating deposition. By using a six-axis robotic system, it enables the access to complex geometries such as fillets, curved surfaces, and side features.

References

| Réference | Name | Status / Price | Datasheet |

|---|---|---|---|

| ARTICLE ZINC FLAKE | Non-Contact Coating Thickness Measurement of Zinc-Flake Coatings on Brake Discs |

Available

On quotation |

English French |

| APPLICATION NOTE - Zinc Flake | Controlling Anticorrosion Paint on Brake Discs |

Available

On quotation |

English French |