Applications / e-coat

E-coat thickness measurement on large and complex automotive parts

With the rapid growth of the electric vehicle fleet, manufacturers are facing increasing challenges in the surface treatment of critical parts using electrophoretic deposition (E-coat / KTL).

Beyond the automotive industry, e-coat is widely used across many industrial sectors. From electronical enclosure, to industrial equipment, and energy related components, e-coat treatment stands as a superior method for protecting structures from corrosion.

E-coat quality control is essential in the automotive industry

E-coat provides long-lasting corrosion protection for large and sensitive parts such as car bodies and battery covers. The key challenge is therefore not to reach an average target thickness, but to ensure sufficient local thickness homogeneity across the entire component in order to guarantee the functional performance of the E-coat.

As a result, OEM (Original Equipment Manufacturer) specifications impose strict requirements on e-coat thickness, uniformity, and corrosion resistance, making it essential to perform a reliable and repeatable control of e-coat.

Why the E-coat process is requiring precise thickness control

E-coat is a dip coating process in which a conductive metal part is coated with paint using an electric field and then baked to form a durable protective film.

Thus, e-coat application remains technically demanding, as the deposited thickness is highly sensitive to multiple process parameters, including applied voltage, immersion time, bath temperature and chemistry, as well as the geometry of the part. These factors can lead to significant local thickness variations, particularly on edges, recesses and enclosed areas.

For this reason, precise, repeatable and representative thickness control is essential to secure process stability and coating quality.

Why e-coat thickness is difficult to measure

Electrophoretic deposition is mainly driven by the locally applied electric field, which means that the deposit will be very sensitive to the geometry of the part, resulting in under-thickness in cavities and over-thickness on edges, making the deposit generally uneven. Due to this variety of geometrical constrains, many conventional thickness measurement methods struggle to deliver repeatable and reproducible results. This highlights the need for measurement approaches based on an integrated physical response of the coating–substrate system.

Technical Challenges in e-coat Thickness Measurement

Conventional industrial approaches for measuring E-coat thickness, such as metallographic cross-sections and eddy current/magnetic induction, present significant technical limitations. Destructive cross-sectioning, while considered a reference method, is inherently local, time-consuming and incompatible with representative thickness assessment on large or complex parts. Electromagnetic techniques provide non-destructive point measurements, but their response is highly sensitive to local geometry, surface curvature and substrate properties, resulting in limited repeatability and poor representativity for e-coat. In addition, these methods are restricted to post curing measurements and do not allow effective control of the coating prior to baking, where process deviations could still be corrected.

The Enovasense approach is based on the integrated physical response of the coating–substrate system, making it less sensitive to local geometrical singularities while remaining compatible with complex part geometries and industrial automation.

Intercomparison thickness measurement of E-coat

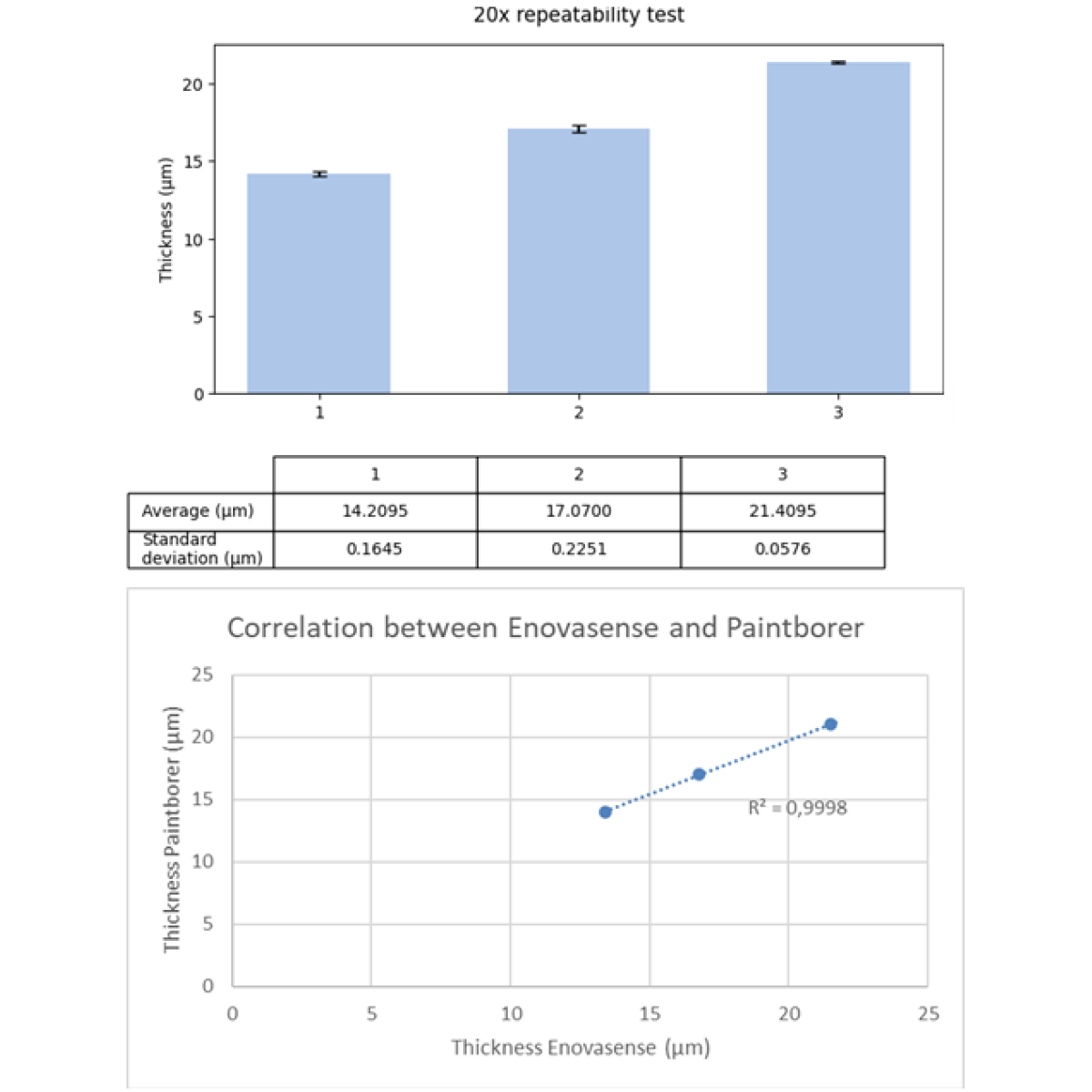

Enovasense technology has been validated on real components supplied by automotive industry manufacturers. To assess measurement accuracy, tests were performed on samples with different E-coat thickness levels, covering the full tolerance range. The Enovasense measurements were then compared with Paintborer measurements, considered here as the destructive reference method.

For this evaluation, three representative measurement locations were selected, with thickness values spanning the entire tolerance interval. At each location, the measurement was repeated 20 times in order to assess repeatability, and the average value and RMS standard deviation were calculated for each position.

A strong correlation was observed between the thickness values measured using the Enovasense method and the reference Paintborer measurements.

Repeatability tests further demonstrate the high stability of the sensors, with consistent results obtained across repeated measurements at identical locations.

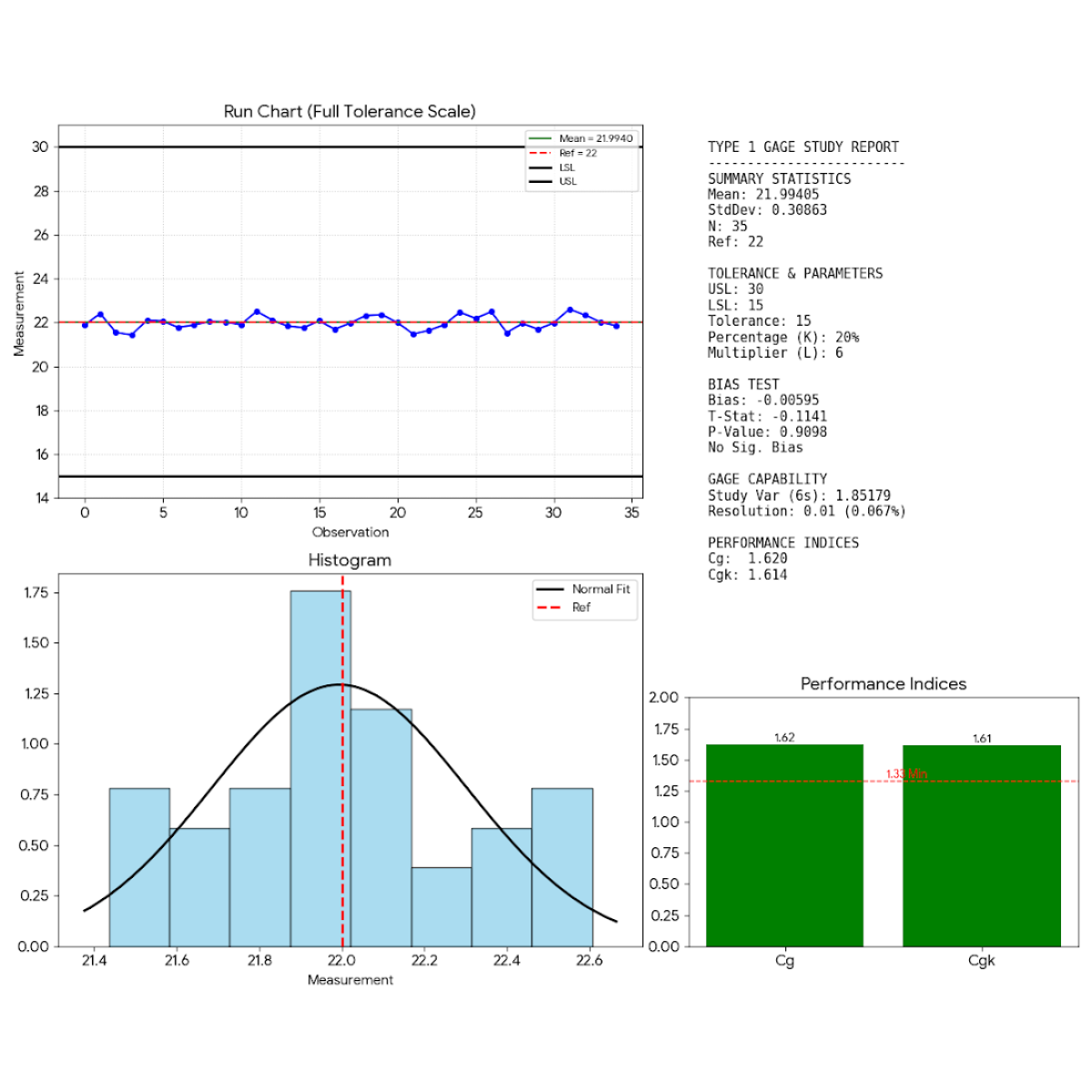

To further assess the intrinsic performance of the measurement system, a Type 1 Measurement System Analysis (MSA) was conducted on a representative sample under controlled conditions.

- Bias : The P-Value (0.910) is higher than the standard alpha level of 0.05. Therefore, the bias is not statistically significant. The measurement system is accurate relative to the reference.

- Capability : Both Cg (1.62) and Cgk (1.61) exceed the standard threshold of 1.33. This indicates that the measurement system is capable. The variation is acceptably small compared to the allocated tolerance.

Impact of the distance on e-coat thickness measurement

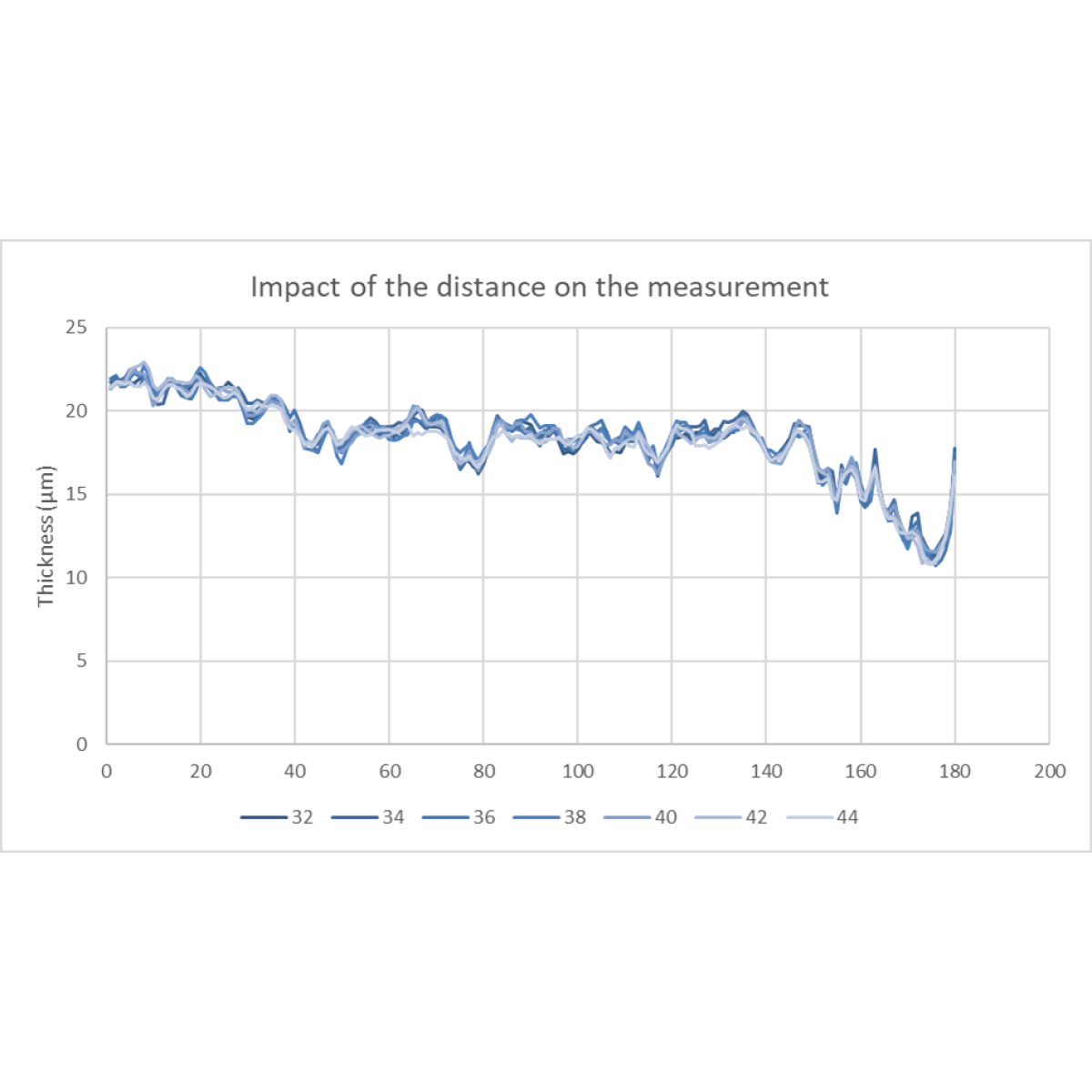

The following tests demonstrate that variations in stand-off distance have a limited impact on E-coat thickness measurement. Measurements performed around the nominal distance 38 mm with +/-6mm variation) exhibit consistent trends, indicating stable measurement behavior within this operating range. Several measurements have been performed along the same line of the same part, showing the variation of the e-coat thickness. This operation was repeated for several stand-off distances.

These results indicate that the integration of Enovasense technology is facilitated by relaxed stand-off distance constraints, while the influence of part geometry on the measurement remains limited. This contributes to robust and repeatable thickness evaluation under industrial conditions.