Applications / thermal spray coatings for aircraft engines

Thickness measurement of thermally sprayed coatings in aircraft engines

Thermally sprayed coatings are absolutely critical to the aircraft engine industry. In fact, many modern jet engines could not operate at their current efficiency or temperature levels without them. These coatings act as a "skin" for engine components, protecting the underlying expensive metals from extreme heat, oxidation, and physical wear.

Thermally spray coatings processes

Thermal spraying is a group of coating processes in which finely divided metallic or non-metallic materials are heated to a molten or semi-molten state and propelled at high velocity onto a prepared surface to create a functional layer.

The aerospace industry uses several specific methods depending on the part. Among the most common:

- Plasma Spray: Uses a high-energy plasma arc to melt ceramic or metal powders. It is the gold standard for applying TBCs to turbine blades.

- HVOF (High-Velocity Oxygen Fuel): Propels particles at supersonic speeds. It creates very dense, tough coatings (like Tungsten Carbide) used for wear resistance on landing gear or compressor blades.

- Cold Spray: A newer technique that uses kinetic energy rather than heat to bond particles.

What are those coatings used for ?

Aircraft engines are embedding various thermally sprayed coatings processes thatcover different purposes. Among them can be counted :

- Thermal barrier Coatings (TBCs) : These are arguably the most critical coatings in modern aviation. They consist of a ceramic top layer (usually Yttria-Stabilized Zirconia or YSZ) that acts as a heat shield. They are located within High-pressure turbine blades, vanes, and combustion liners. They allow the gas temperature to exceed the melting point of the metal components. A well-applied TBC can create a temperature drop of up to 300°C across its thickness.

- Wear and Fretting Resistant Coatings : These are extremely hard coatings, often "Cermets" (Ceramic-Metallic composites) like Tungsten Carbide-Cobalt or extremely hard alloys like Triballoy. They are located into Blade roots, bearing journals, and flap tracks. They allow to prevent fretting, which is wear caused by microscopic vibrations at the interfaces where parts are joined together.

- Environmental and Corrosion Coatings : These coatings (often MCrAlY alloys, where M is Nickel or Cobalt) protect against the the incredibly complex, aggressive, and fast-moving environment inside a jet engine. They are located in compressor blades and turbine "bond coats". They allow to prevent hot corrosion and oxidation.

Why measuring the thickness of such thermally sprayed coatings is critical

The precise measurement of thermally sprayed coatings is a critical safeguard against catastrophic engine failure caused by the extreme mismatch in thermal expansion between ceramic layers and metallic superalloys. If a coating exceeds its specified thickness, the internal residual stresses can trigger spallation, where the protective layer flakes off and exposes the turbine blades to temperatures that exceed their melting point. Conversely, a coating that is too thin fails to provide the necessary thermal gradient, leading to rapid oxidation and structural creep of the engine components. Beyond safety, thickness control is the primary driver of aerodynamic efficiency; in abradable seals, even a micron-level deviation can increase the "tip gap," leading to significant fuel waste and lost thrust. Furthermore, non-uniform application across rotating parts creates centrifugal imbalances that induce high-cycle fatigue and dangerous engine vibrations.

How to measure the thickness of aircraft engine thermally sprayed coatings ?

Besides destructive cross section microscopy, a range of non-destructive techniques are available for measuring the thickness of such coatings :

| Criteria | Enovasense laser photothermal | Eddy currents / Magnetic induction | Ultrasonic testing |

|---|---|---|---|

| Measurement principle | Thermal diffusion response | Electromagnetic field interaction | Time-of-flight of sound waves |

| Contact / Non contact | Non contact | Contact | Contact |

| Operator impact | Independent of operator | Operator dependent (how the contact is applied) | Operator dependent (how the coupling is applied) |

| Recalibration | No recalibration needed | Needs regular recalibration | Needs regular recalibration |

| Size, shape and edge dependency | Independent of shape, curvature or geometry | Shape dependent. Not working close to edges and holes | Shape dependent. Not working close to edges and holes |

| Thermal Barrier Coating ability | Works on the typical range of [50-450µm] | Works on the typical range of [50-450µm] | Does not work on the typical range of [50-450µm] |

| Wear and Fretting Resistant Coatings | Works on Cermets like WCCo and Triballoy | Cermet and Triballoy coatings will complicate things due to their partly conductive and partly magnetic properties | Does not work for the low thickness range |

| Environmental and Corrosion Coatings | Works on MCrAlY coatings | MCrAlY coatings and their substrates are both electrically conductive, complicating the measurements | MCrAlY coatings and their substrates are similar in acoustic impedances : not working |

The Enovasense laser photothermal technology allows an easy noncontact measurement, with clearly lower dependency to part shape and geometry. It is also fitted for most of thermally sprayed coatings for aircraft engines applications, while other techniques show difficulties or impossibilities on many of those cases.

How Enovasense performs on aircraft engines thermally sprayed coatings

Thermal barrier coatings (TBCs) act as essential insulating blankets for jet engine components, allowing turbine blades to survive gas temperatures that far exceed the melting point of their underlying metallic superalloys. These ceramic layers create a vital thermal gradient that ensures structural integrity while significantly boosting engine thrust and fuel efficiency through higher operating temperatures. Precise thickness monitoring is critical because a coating that is too thin fails to protect the metal from overheating and creep, while an excessively thick layer is prone to delamination and spalling due to internal mechanical stresses. Furthermore, because TBCs gradually degrade through erosion and chemical exposure during flight, accurate measurements allow maintenance teams to predict component lifespans and prevent catastrophic mid-air failures. By maintaining the exact specified thickness, aerospace engineers can balance the aggressive pursuit of performance with the uncompromising necessity of flight safety.

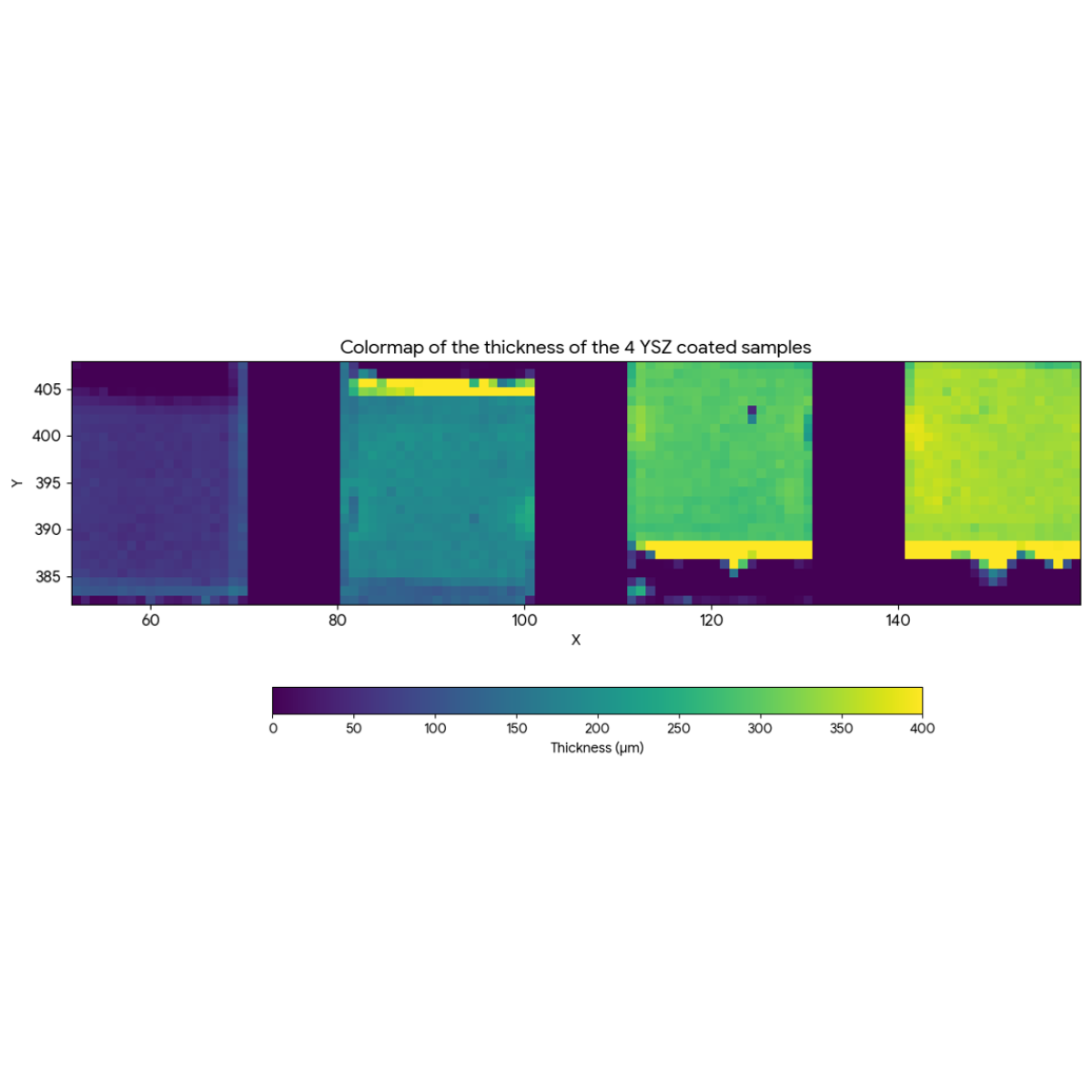

The feasibility study was performed on 4 flat coupons coated with YSZ (Yttria-Stabilized Zirconia) deposited through APS (Atmospheric Plasma Spray) with various thickness levels going from 47 µm to 374µm. Each sample had a dimension of 10mmx10mm so some small inhomogeneity of the deposition was expected within each sample.

An Enovasense Point sensor was used with the following parameters : Wavelength of 980nm, laser maximum power 10W, measuring time 1.7s, distance probe-part 35mm and laser spot diameter of 3,3mm. This spot size was chosen to be large enough to average the possible thickness variation expected at a submilimetric level linked to the thermal spray process. The sensor was then placed into a 3 axes control station and a 2D mapping of each sample was performed with a 1 millimeter step in both directions. The mapping is then displayed in the following colormap

Colormap of the thickness of the 4 YSZ coated samples (Enovasense Point sensor mapping)

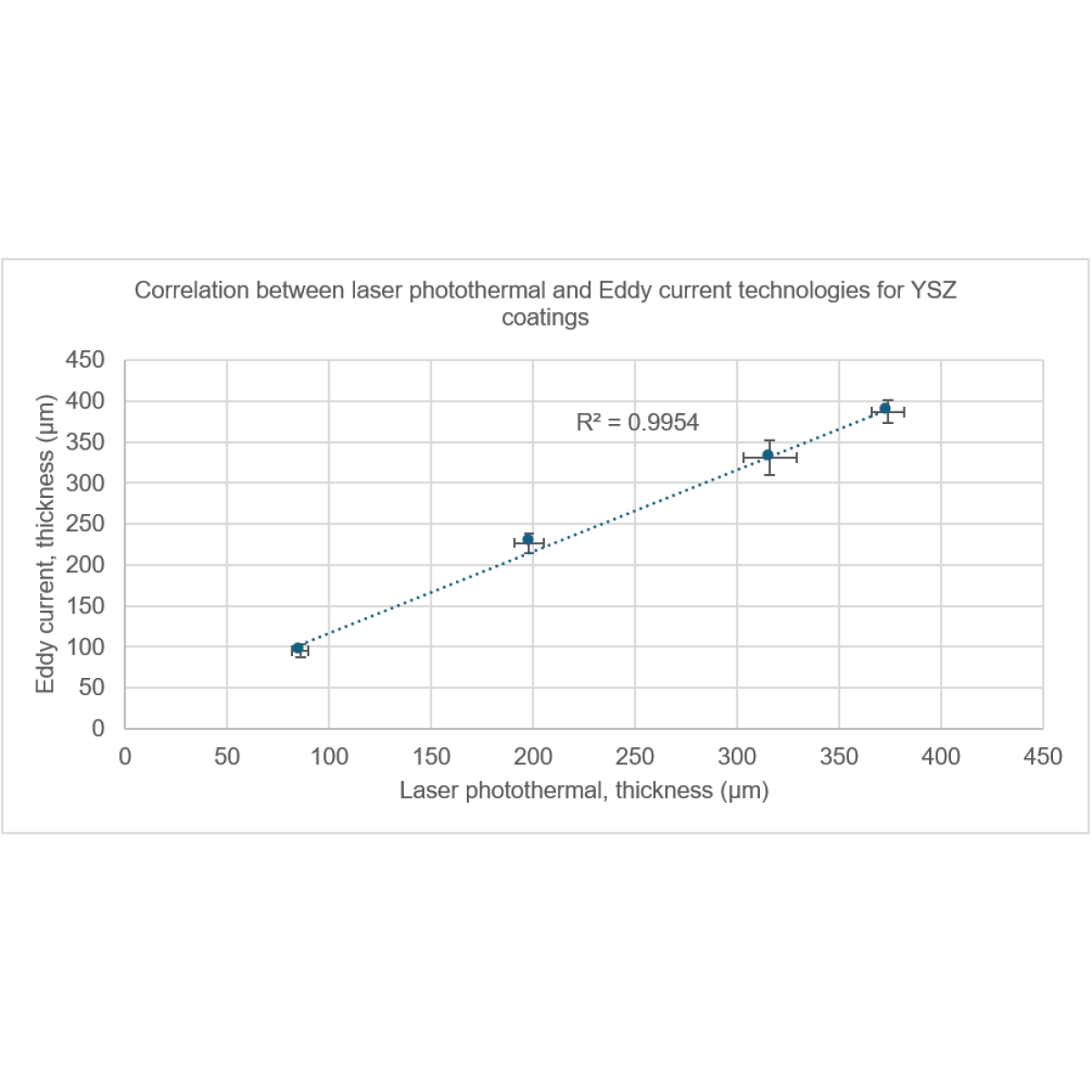

Those measurements are then correlated to some Eddy current readings realized (10 positions per sample). Regarding both technologies, the average value and the standard deviations were used for the intercomparison.

Correlation between laser photothermal and Eddy current technologies for YSZ coating thickness

While a 99.5% correlation is observed between both techniques, it is observed that the Eddy current tend to overestimate slightly the YSZ thickness due to the peak effect described above. Additionally, the laser photothermal measurements report a lower standard deviation than the Eddy current measurements.

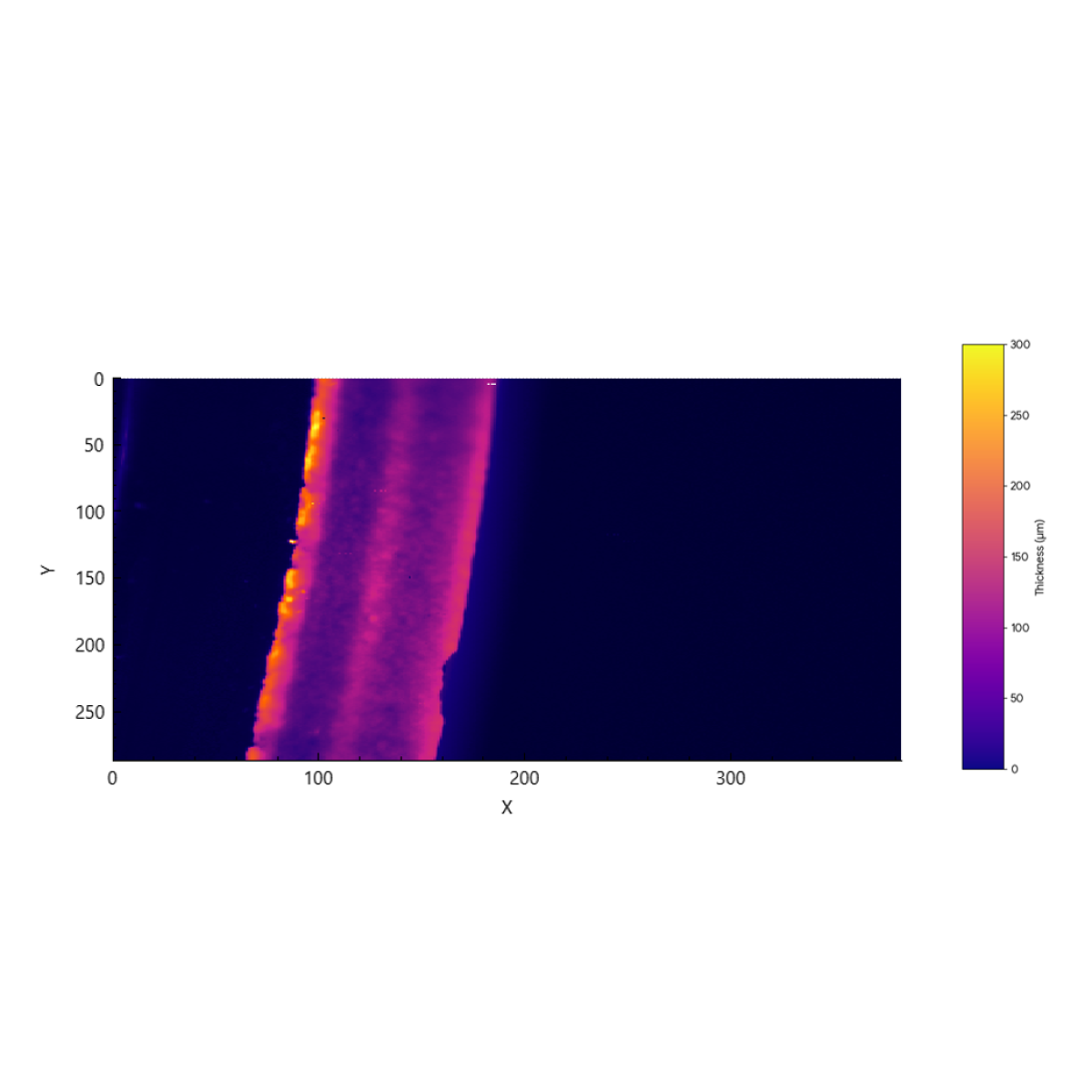

But the main advantage of laser photothermal is that it can easily be applied to non-flat samples – real parts-, as there is no need for a contact with the part and as there are no impact of the geometry, curvature or proximity to and edge. Particularly, the case of aircraft engines turbine teeth is especially delicate in terms of geometry since the area of interest is located at the top of the very thin tooth. In this area, a thermal barrier coating of at least 100µm is deposited on an sharp area of a size lower than 1 millimeter. While this challenge seems impossible for most of the coating thickness measurement technologies, it is clearly measurable with a laser photothermal field sensor.

In the following figure, an Enovasense Field sensor has been used to provide a full mapping of the part with a 55µm spatial resolution in a 1-second shot. This allows to quantify the thickness of the coating very locally in every position of the turbine tooth, including the sharp end.

Coating thickness colormap of a turbine tooth captured with the Enovasense Field sensor

How to integrate Enovasense sensors for controlling such coatings

The Enovasense probes are compact and lightweighted which allows to imagine various integration possibilities :

- Robotic integration or fixed positionning

The very compact Enovasense probe can be implemented on a robotic arm and then automatically control various positions of the part to measure.

- Offline control station

The HKL2 control station allows to perform thickness mapping and cycles of movements and measurements in order to automatically measure various positions on the part. For smaller parts, it can also measure automatically batches of parts.

References

| Réference | Name | Status / Price | Datasheet |

|---|---|---|---|

| PLASMA | Thickness measurement of metallic and ceramic coatings deposited by plasma spray thermal projection |

Available

On quotation |

English French |

Documents

| Type | Name | Download |

|---|---|---|

| Application | Thermal spray | English French |

| Application | Controlling the thickness of thermally sprayed coatings | French |